Lift ouni Getriebe Traktiounsmaschinn THY-TM-1

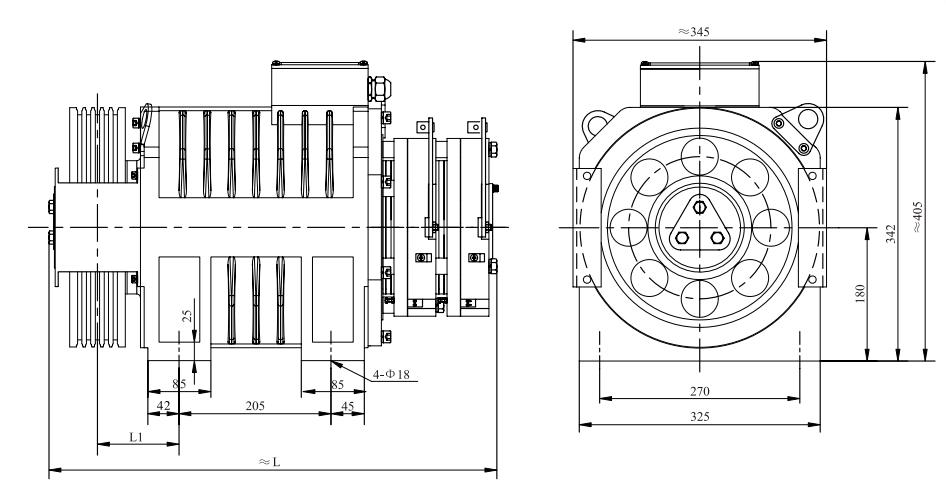

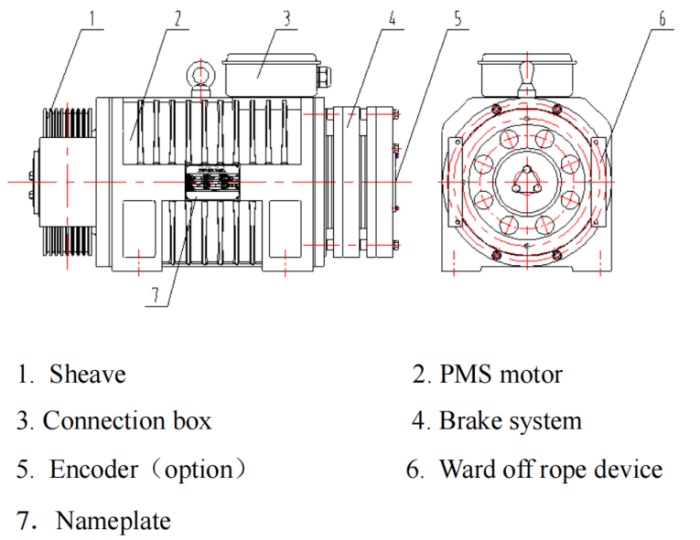

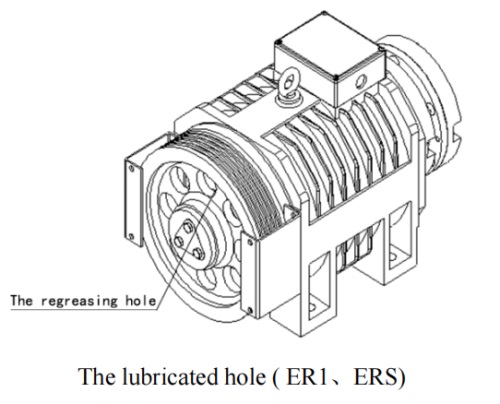

Den THY-TM-1 synchronen Permanentmagnet-Lifttraktiounsmaschinn ouni Getriebe entsprécht den Normen TSG T7007-2016, GB 7588-2003, EN 81-20:2014 Sécherheetsregelen fir de Bau an d'Installatioun vun Liften - Liften fir den Transport vu Persounen a Gidder - Deel 20: Persounen- a Gidderliften an EN 81-50:2014 Sécherheetsregelen fir de Bau an d'Installatioun vun Liften - Prüfungen an Tester - Deel 50: Konstruktiounsregelen, Berechnungen, Prüfungen an Tester vu Liftkomponenten. De Bremsmodell, deen der Lifttraktiounsmaschinn entsprécht, ass SPZ300. Gëeegent fir eng Liftbelaaschtung vun 630 kg ~ 1000 kg, 630 kg Nenngeschwindegkeet 1,0 ~ 2,0 m/s, Duerchmiesser vun der Zuchscheif Φ320; 800 kg an 1000 kg Nenngeschwindegkeet 1,0 ~ 1,75 m/s, Duerchmiesser vun der Zuchscheif Φ240; Recommandéiert Lifthiewhéicht ≤80 Meter. D'Schutzofdeckung vum Traktiounsrad ass an en vollschléissenden an en hallefschléissenden Typ opgedeelt. Dräiphaseg AC Permanentmagnet-Synchron-Innererotormotor Strukturtyp, Schutzklass IP41. Getriebefräi Traktiounsmaschinne si mat engem mechanesche Fernbremsentloosser ausgestatt, deen benotzt gëtt fir d'Brems manuell opzemaachen, wann e Liftaccident geschitt. Versicht den Drot vum Bremsentloosser während der Installatioun net ze béien. Wann d'Béien vun der Bremsentloossungsleitung onvermeidbar ass, muss de Biegradius méi grouss wéi 250 mm sinn, soss kann et zu enger geféierlecher Situatioun vu Bremsausfall féieren. Nodeems Dir den Haaptmotor mam Fernbremsentloosser benotzt hutt, ass et néideg ze bestätegen, ob d'Brems komplett zréckgesat ass, ier den nächste Betrib ufänkt. D'Brems ass ee vun de wichtegste Sécherheetskomponenten vum Liftsystem!

1. Schnell Liwwerung

2. D'Transaktioun ass just den Ufank, de Service héiert ni op

3. Typ: Traktiounsmaschinn THY-TM-1

4. Mir kënnen synchron an asynchron Traktiounsmaschinne vun TORINDRIVE, MONADRIVE, MONTANARI, FAXI, SYLG an aner Marken ubidden.

5. Vertrauen ass Gléck! Ech wäert Äert Vertrauen ni enttäuschen!

D'Method fir d'Ouverture vun der Brems SPZ300 unzepassen:

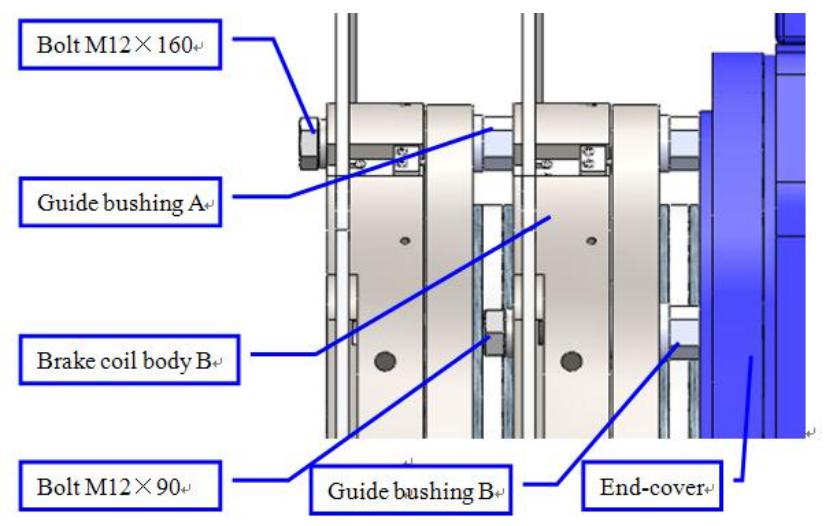

Werkzeug: Gaffeschlüssel (18mm, 21mm), Kräizschrauber, Fühlermessgerät

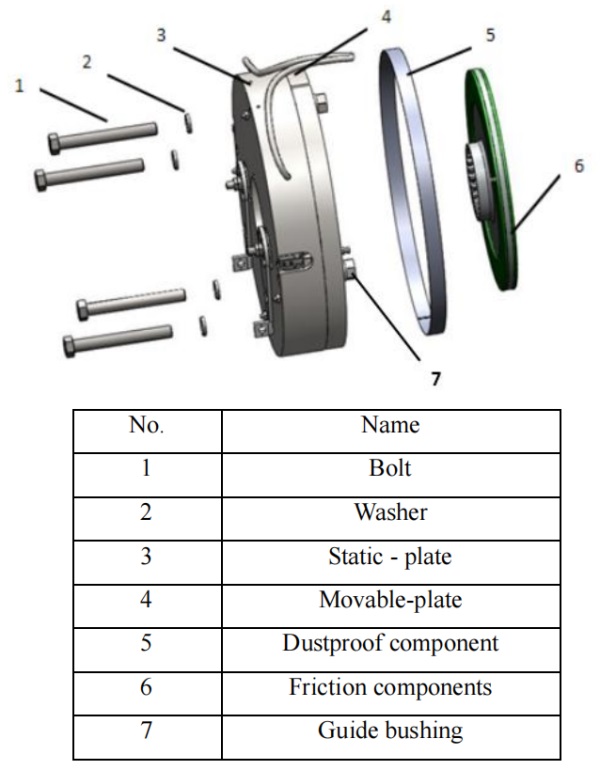

Inspektioun: Wann den Lift am Parkzoustand ass, benotzt e Kräizschrauber fir d'Schrauf M4x16 an d'Mutter M4 auszeschrauben, an huelt de Staubsicherring vun der Brems ewech. Benotzt e Fühlermooss fir d'Spalt tëscht der beweeglecher an der statescher Placke festzestellen (10°~20° vun der entspriechender Positioun vun 3 M12x160 Schrauwen an der entspriechender Positioun vun 3 M12x90 Schrauwen). Wann d'Spalt méi wéi 0,35 mm ass, muss se ugepasst ginn.

Upassung:

1. Benotzt e Gängschlüssel (18mm) fir d'Schraube M12x160 an d'Schraube M12X90 ongeféier eng Woch laang ze léisen.

2. Verstell den Ofstandsstéck A an den Ofstandsstéck B lues mat engem Gängschlüssel (21mm) fir sécherzestellen, datt den Ofstandsstéck B net géint d'Réckdeckel vun der Haaptunitéit kënnt, an datt den Ofstandsstéck A net géint de Bremsspulesëtz B kënnt.

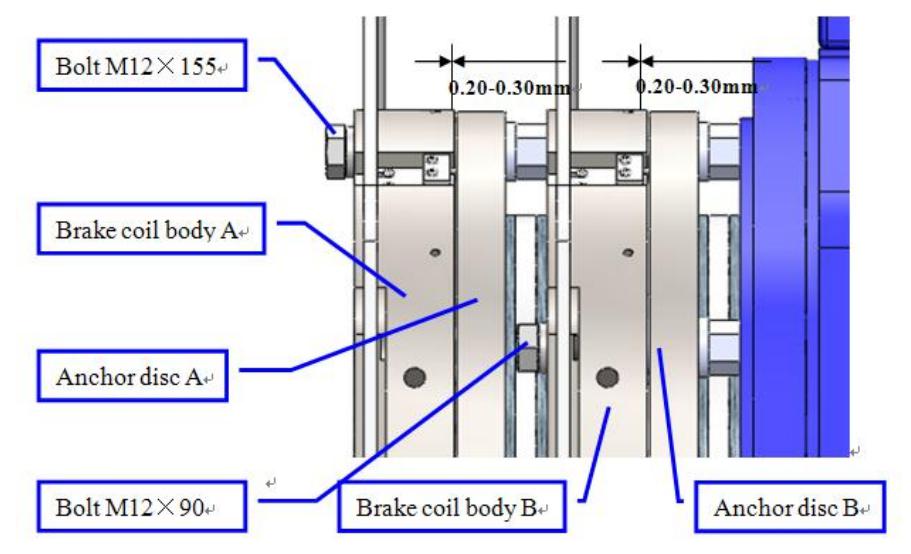

3. Stellt d'Schrauf M12x90 sou an, datt d'Spalt tëscht der Bremsspulenbasis B an dem Bremseisenkär B 0,2 mm ass. Stellt d'Schrauf M12X160 sou an, datt d'Spalt tëscht der Bremsspulenbasis A an dem Bremskär A 0,2 mm ass.

4. Stellt den Ofstandshalter B sou an, datt d'Spalt tëscht der Bremsspulenbasis B an dem Bremseisenkär B 0,25 mm ass. Stellt den Ofstandshalter A sou an, datt d'Spalt tëscht der Bremsspulenbasis A an dem Bremskär A 0,25 mm ass. Wann d'Spalt ze grouss ass, stellt den Ofstandshalter géint den Auerzäresënn an ëmgekéiert.

5. D'Schraube M12x90 sou festzéien, datt d'Ofstand tëscht der Bremsspulenbasis B an dem Bremskär B 0,2~0,3 mm ass. D'Schraube M12X155 sou festzéien, datt d'Ofstand tëscht der Bremsspulenbasis A an dem Bremskär A 0,2~0,3 mm ass.

Spannung: 380V

Suspension: 2:1

SPZ300 Brems: DC110V 2×1.0A

Gewiicht: 230 kg

Maximal statesch Belaaschtung: 2200 kg